Our Market and

Product Details

Zinc flake coatings

Overview

What is Zinc Flake Coating?

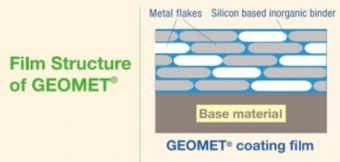

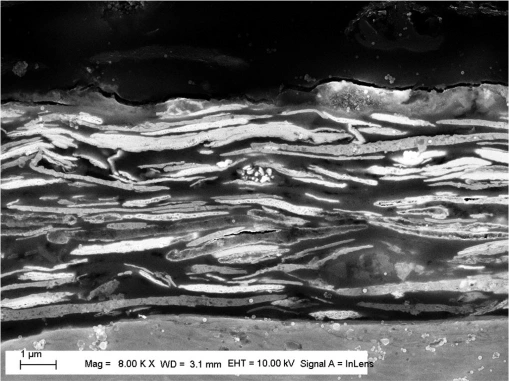

Zinc flake coatings consist of a combination of zinc and aluminum flakes suspended in a binder or resin matrix. The flakes form a layered structure on the surface, creating a barrier that shields the metal from environmental factors such as moisture, salt spray, and chemicals. This layered structure also offers cathodic protection to the underlying metal, which means that even if the coating is damaged or scratched, the zinc flakes sacrificially corrode instead of the metal substrate, providing an added level of protection.

These coatings are typically applied using a spray or dip process and then cured through heat or air drying. They can be used as standalone coatings or as part of a multilayer coating system, where they serve as a base layer for additional paint or powder coatings.

What is GEOMET ®

GEOMET coating film has a silver-metallic look. Layers of metal flakes are connected with one another through the use of a special inorganic binder.Because the film is extremely thin-only about 8um-it won’t negatively affect the optimal fit between bolts and nuts.

2C2B is the standard manufacturing process.

How it works?

Barrier effect

The positioning of the zinc flakes gives the film a barrier effect that isolates the metal from the corrosive environment. Indeed the flake morphology increases the length of the path that the aggressive substances must travel to reach and corrode the substrate.

Sacrificial protection

Self Healing

Adhesion to substrate

Benefits of Zinc Flake Coating:

Exceptional Corrosion Resistance:

The zinc flake layer acts as a sacrificial barrier, providing outstanding corrosion protection to the underlying substrate. It offers superior resistance against moisture, chemicals, salt, and other corrosive elements, thereby significantly extending the lifespan of coated products.

Uniform Coating Thickness:

The application of zinc flake coating ensures consistent and uniform thickness across complex geometries, including recessed areas and threaded surfaces. This ensures comprehensive coverage and protection for all parts of your products, even those with intricate designs.

High Temperature Performance:

Zinc flake coatings are designed to withstand high-temperature environments, making them suitable for applications where exposure to heat is a concern. This makes the coating ideal for automotive, aerospace, and industrial components.

Low Environmental Impact:

Zinc flake coatings are environmentally friendly, as they are free from harmful heavy metals like lead and chromium. Additionally, the coating process itself involves minimal waste generation and can be easily applied using eco-friendly techniques.

Versatile Application:

Zinc flake coatings can be applied to various substrates, including steel, aluminum, and other metal alloys. This versatility makes it an excellent choice for a wide range of industries, such as automotive, construction, marine, and oil and gas.

GEOMET ®

GEOMET® 720

Corrosion protection

^ Results depend on substrate, geometry of parts and type of application processes.

720-2000 h

(ISO 9227/ASTM B117)

Temperature resistance

Static friction

Electrical properties

Paintability

No hydrogen embrittlement

GEOMET® 321

Corrosion protection

720-2000 h

(ISO 9227/ASTM B117/JIS Z2371)

Temperature resistance

Static friction

Electrical properties

Paintability

No hydrogen embrittlement

GEOMET® 500

Corrosion protection

720-2000 h

(ISO 9227/ASTM B117/JIS Z2371)

Lubrication

0.12-0.18

(ISO 16047}

Temperature resistance

Electrical properties

Paintability

No hydrogen embrittlement

ZINCROKOTE®

SIMPLIFIED TECHNOLOGY with GOOD PERFORMANCE

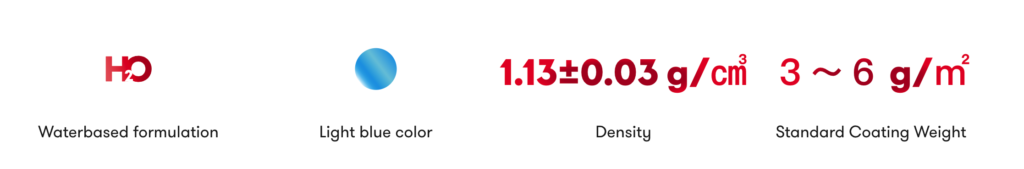

ZINCROKOTE® is a zinc flake anticorrosion coating using water- based chemistry. Derived from reference technologies developed by NOF METAL COATINGS, it is applied in 2 coats and meets corrosion resistance requirements up to 400 hours in salt spray test.

Coating with metallic silver appearance consisting of:

1 basecoat coat + 1 topcoat coat

Thin dry film, non electrolytic

- Water-based chemistry

Free from hexavalent and/or trivalent chromium, nickel and cobalt Passivated zinc and aluminum flakes in a binder

Characteristics and performance

- Adjustable coefficient of friction thanks to PLUS-family topcoats

- Performance maintained at elevated temperatures (up to 300C) .

- Electrical conductivity for most application

- Bimetallic compatibility with aluminum

- No hydrogen embrittlement

- Paintable coating

Corrosion resistance

Average thickness Salt Spray

Test (ISO 9227)

6 μm

> 72 hours without white rust

> 400 hours without red rust

Application processes

ZINCROKOTE® can be applied by Dip-Spin, using bulk or rack coating process

Health and Safety

- Aqueous dispersion

- Complies with REACH

Complies with the 2011/65/EU and (EU) 2015/863 directives

International standards

ISO 10683 – Fasteners: non-electrolytically applied zinc-flake coatings

EN 13858 – Non-electrolytically applied zinc-flake coatings on iron or steel parts

ASTM F1136/F1136 M – Zinc/Aluminum Corrosion Protective Coatings for Fasteners

Topcoats

Torquer Series

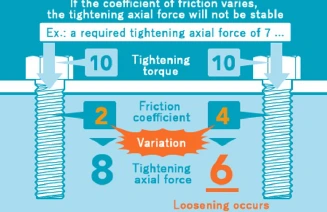

Preventing looseness / Cost reduction / Weight reduction The Torquer Series is effective in every situation

Increasing the size and number of bottles is not enough to prevent loosening.

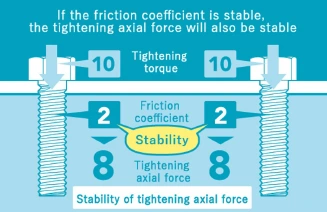

The most effective way to prevent loosening is to stabilize the coefficient of friction and exert an appropriate tightening axial force.

01. Stable fasteninig axial force prevent looseness

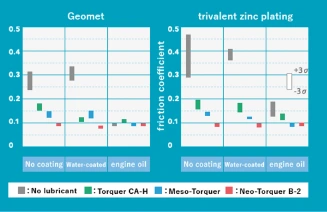

02. A stable friction coefficient

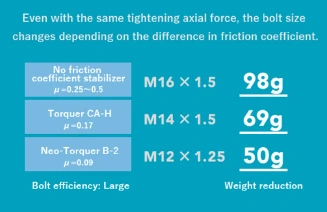

03. Maximize the utilization of bolts without sacrificing performance

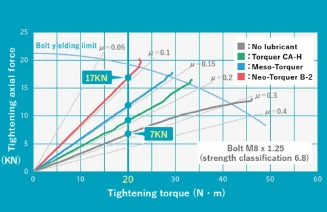

When the tightening torque is 20N*m, with M8 x 1.25 bolts (strength classification 6.8), only 7KN of tightening axial force can be obtained with non-lubricated bolts. However, when Neotorquer is applied, a tightening axial force of 17KN can be obtained.

In this way the Torquer series can maximize bolt performance.

04. No more increasing the size ir the number of bolts

PLUS® VL

Lubrication

0.09-0.14

Coefficient of friction (ISO 16047)

Corrosion

protection

Chemical

resistance

Color tracing

No hydrogen embrittlement

PLUS® VLh

Lubrication

0.09-0.14

Coefficient of friction (ISO 16047)

Corrosion

protection

Chemical

resistance

Color tracing

No hydrogen embrittlement

PLUS® ML

Lubrication

0.10-0.16

Coefficient of friction (ISO 16047)

Corrosion

protection

Chemical

resistance

Color tracing

UV tracing

No hydrogen embrittlement

PLUS® ML Black

Lubrication

0.10-0.16

Coefficient of friction (ISO 16047)

Cosmetic

Corrosion

protection

Chemical

resistance

No hydrogen embrittlement

PLUS® M

Lubrication

0.12-0.18

Coefficient of friction (ISO 16047)

Corrosion

protection

Temperature

resistance

Chemical

resistance

No hydrogen embrittlement

PLUS XL

Lubrication

0.06-0.09

Coefficient of friction (ISO 16047)

Corrosion

protection

Chemical

resistance

No hydrogen

embrittlement

PLUS L

Lubrication

0.08-0.14

Coefficient of friction (ISO 16047)

Corrosion

protection

Chemical

resistance

Color tracing

No hydrogen embrittlement

Plus 10

Corrosion protection

Chemical resistance

No hydrogen embrittlement

GEOMETPLUS® JL Blue

Lubrication

0.14-0.20

Coefficient of friction (ISO 16047)

Corrosion protection

Chemical resistance

GEOMETPLUS® JL Black

Lubrication

0.17-0.23

Coefficient of friction (ISO 16047)

Coloration

Corrosion

protection

Chemical

resistance

ECHOTE® WH700