Aum Dacro

Coating process

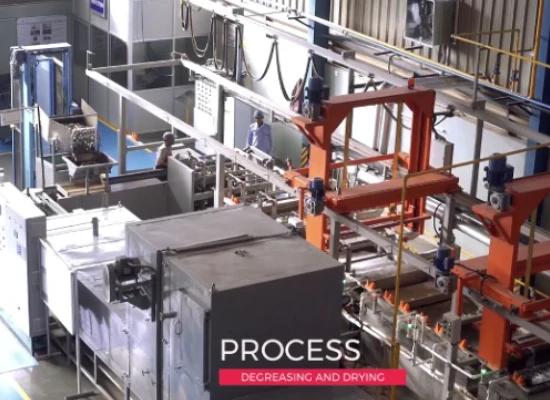

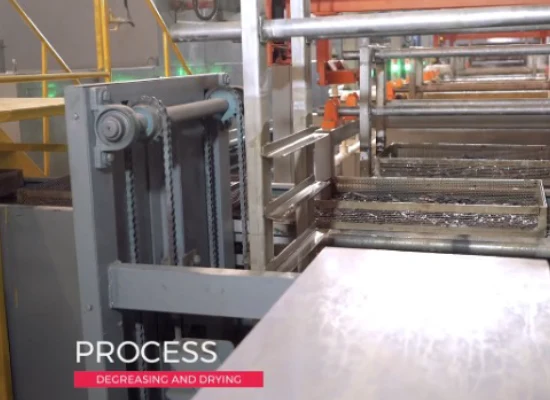

1. Degreasing / Drying

It is necessary to remove the soil from the parts as treating material which may have some oils while processing. rust prevention oil for protecting the rust before GEOMET®720LS

2. Shot Blasting

The purpose of blasting is to expose fresh metal surface oy femora inorganic so, rust, and scale from the surface of the part by mechanical force. To cos enough sacrificial protection it is necessary to get good contact between zinc and steel surface, for example, the scale could interfere to flow of the electric current.

There are various types of blasting machines used for different types of products.

Hanger type shot blasting

Tumble Type Shot blasting

Table Type Shotblasting

Sandblasting

3. Coating And Curing

The purpose of this process is to apply enough zinc and aluminium flake paint on the parts surface with uniformity.

The processes are largely classified into the following types:

A. Spray method

This coating method is ideal for parts that must maintain a good appearance. Suspend the parts from a hanger and perform electrostatic coating and then bake them in the oven. The standard specification is one coat and one bake.

Basket Spray

In this process chemical is sprayed in a continuously rotating basket.

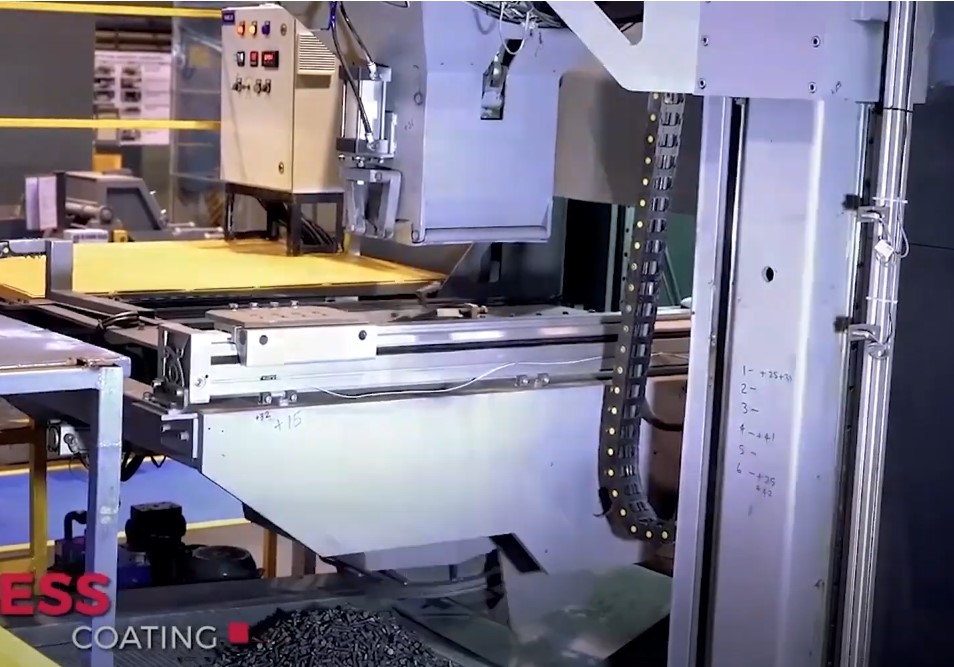

B. Dipspin Method

Application to bulk quantity(dip-spin ) is carried out in baskets which allow eliminating the excess liquid on the surface of the parts and improving the distribution of the coating

Single Basket Coating Machine

In this process chemical is sprayed under the pressure of atomizing air. It can be carried with pneumatic air guns or electrostatic equipment

3 Basket Robotic Coater

In this process chemical is sprayed in continuously rotating basket.

6 Basket Planetary Coating Machine By Sidasa

4. Curing Process

Geomet® film is formed by heat up the metal surface coated with Geomet®. The curing process of Geomet® is consisted with 2 stages. Vaporising water and organic solvent and following film form reaction.

5.Final Inspection

In this stage 100% inspection takes places for coating defects. The approved material is packaged and dispatched.

6. Testing Facilities

Salt spray testing is a laboratory simulation of a corrosive saline environment. It is used as an accelerated means of testing the ability of surface coatings to withstand atmospheric corrosion. Also known as salt fog testing,

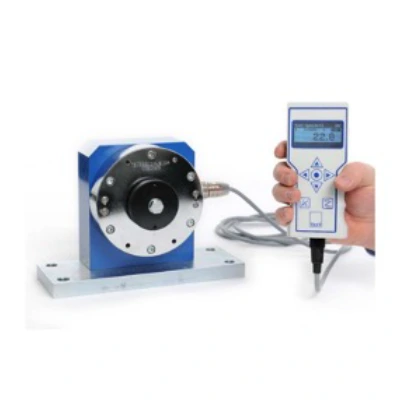

CoF Testing Machine

Salt Spray Test

XRF Machine

Advanced Optical Digital Microscope

LAb batch oven

Lab Coater