Enhancing Performance and Durability: The Role of Curing in Zinc Flake Coating

Introduction:

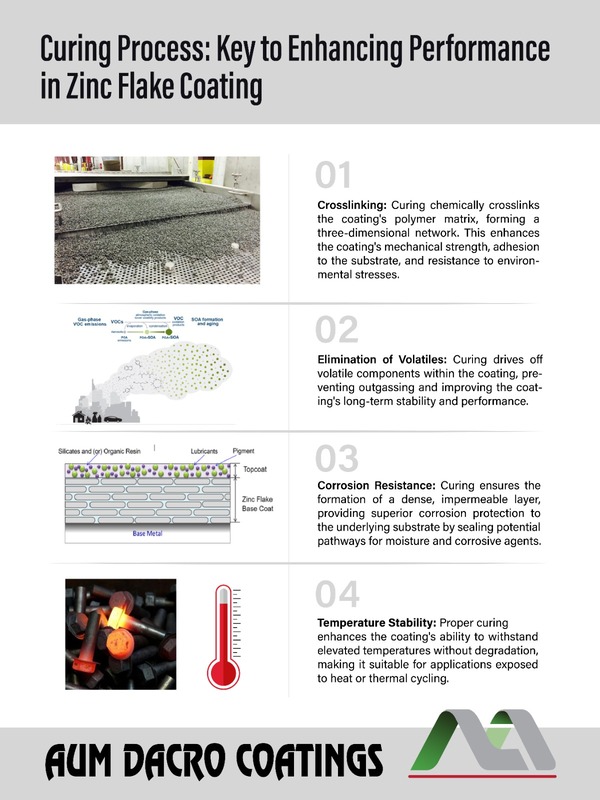

Zinc flake coating is a popular method for providing corrosion protection to metal surfaces in various industries. One key aspect of this coating process that significantly enhances its performance and durability is the curing process. Curing chemically crosslinks the coating’s polymer matrix, forming a three-dimensional network. This article explores how the curing process in zinc flake coating contributes to its advantageous properties and why it is essential for achieving long-lasting protection.

Curing Improves Resistance To Environmental Stresses:

In addition to enhancing mechanical properties, curing also improves the coating’s resistance to environmental stresses. The crosslinked polymer matrix provides a barrier that protects the underlying substrate from exposure to moisture, chemicals, and other environmental factors. This enhanced resistance ensures that the coating maintains its integrity and performance even in harsh conditions.

Curing Prevents Outgassing And Improves Stability:

Another advantage of curing in zinc flake coating is its ability to drive off volatile components within the coating. This prevents outgassing, which can lead to defects in the coating and reduce its long-term stability. By removing these volatile components, curing improves the coating’s stability and performance, ensuring that it remains intact and effective over time.

Enhanced Thermal Stability:

Furthermore, curing enhances the coating’s ability to withstand elevated temperatures without degradation. This is crucial for applications exposed to heat or thermal cycling, where the coating must maintain its integrity and protective properties. The crosslinked polymer matrix provides thermal stability, ensuring that the coating performs effectively under high-temperature conditions.

Superior Corrosion Protection:

Perhaps most importantly, curing ensures the formation of a dense, impermeable layer that provides superior corrosion protection to the underlying substrate. By sealing potential pathways for moisture and corrosive agents, the cured coating prevents corrosion from occurring and extends the lifespan of the coated metal surfaces.

Conclusion:

In conclusion, the curing process plays a crucial role in enhancing the performance and durability of zinc flake coating. By chemically crosslinking the coating’s polymer matrix, curing improves its mechanical strength, adhesion, resistance to environmental stresses, and thermal stability. It also prevents outgassing and enhances the coating’s corrosion protection properties. For quality zinc flake coating solutions, contact Aum Dacro and experience the difference in protection and performance.